Astyx MPS

We are disrupting the hydraulics market with unique sensor technology that turns any hydraulic cylinder into a smart cylinder. Using electromagnetic waves in the RF spectrum, a single sensor can measure the position and velocity of the piston inside the hydraulic cylinder with mm-precision. These smart cylinders will significantly enhance efficiency, comfort and safety of our customers’ products and are a key enabler for autonomy and automation of industrial systems.

Products

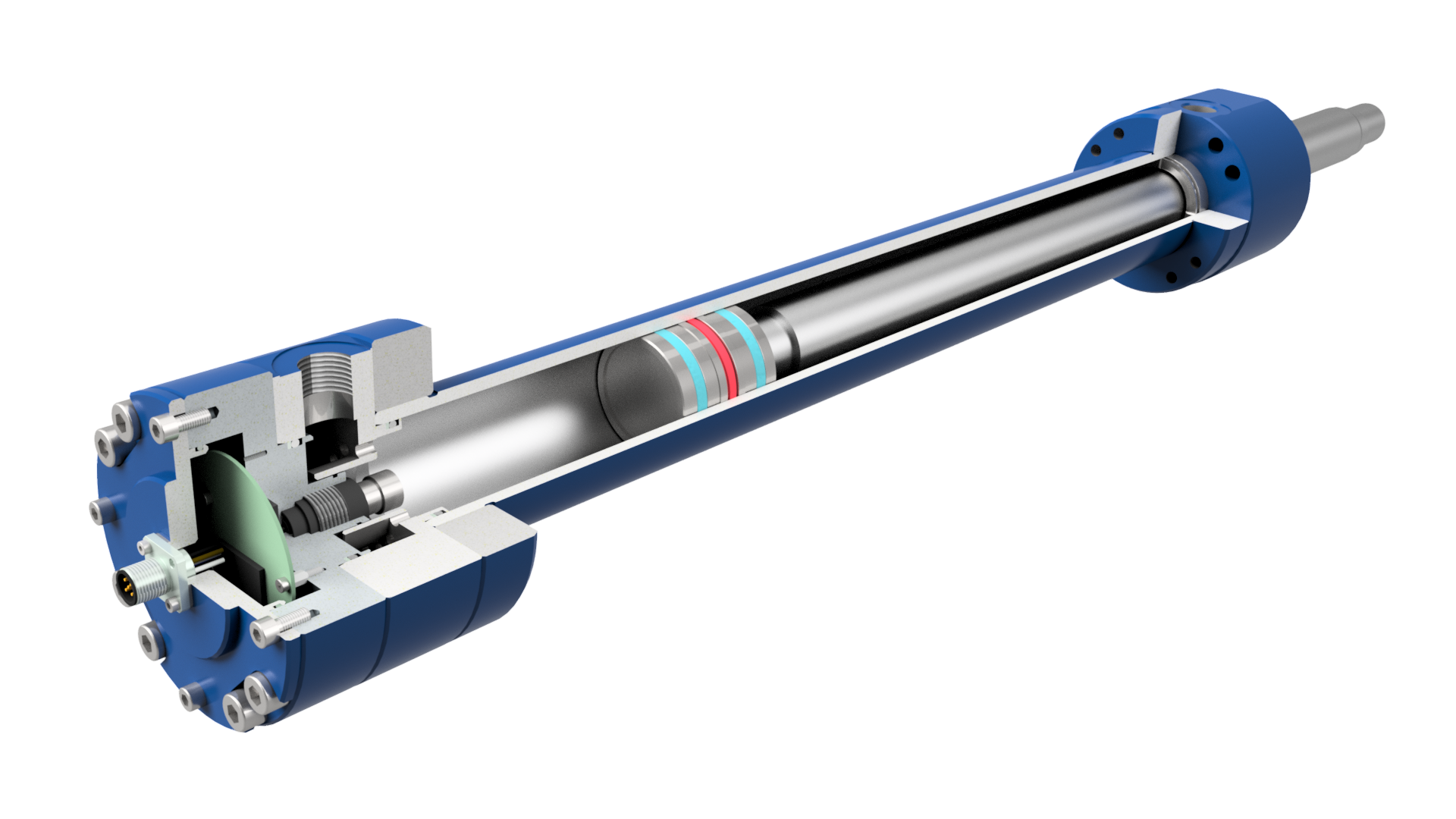

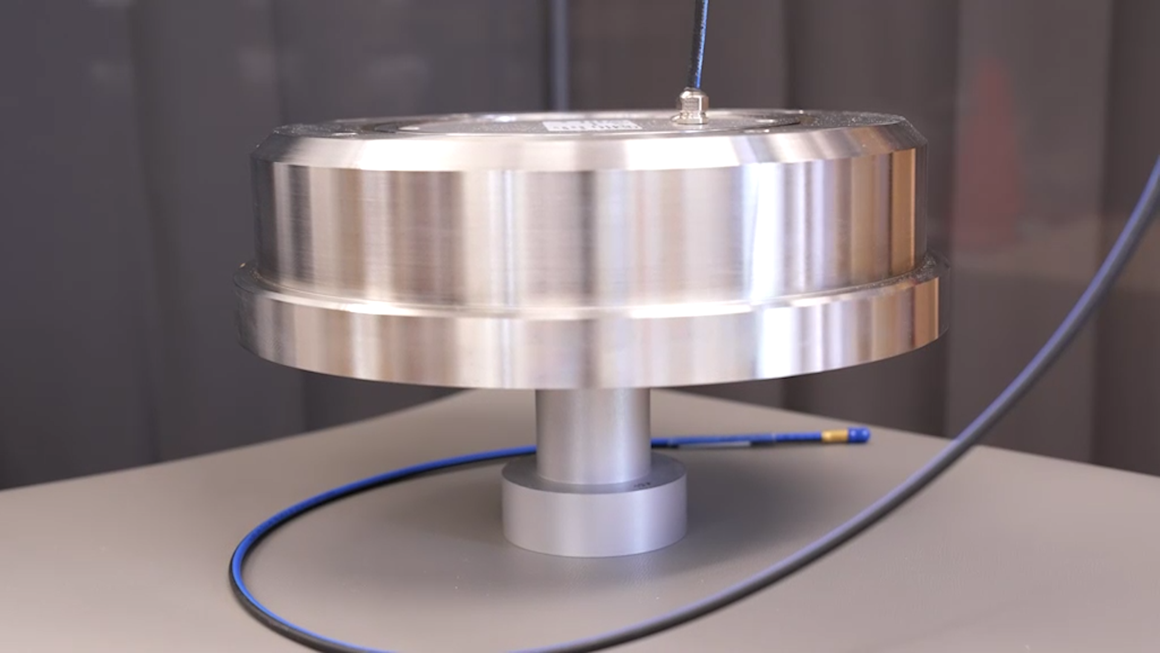

We have been developing and manufacturing customized solutions for piston position sensors for several years and are now progressing into high-volume industrial markets. The working principle of our unique technology is as follows: Electromagnetic waves are being emitted into the hydraulic cylinder using a proprietary antenna design. These microwaves are being reflected at the piston. The position and velocity of the piston is calculated by analysis of the phase difference of the emitted and the received signal. Other than existing solutions, our products do not require costly processing/ drilling of the hydraulic cylinder or piston and are free of moving mechanical parts, thus offering maximum robustness and clear economic benefits for our customers. With our proprietary software solution and OTA access, we can calibrate and update our sensors in the field fully remote. Additionally, we are able provide preventive maintenance data such as usage, pressure and temperature (peaks) for our customers’ cylinders for the first time.

Hydraulic sensors

Our hydraulic sensors can be used in numerous mobile and stationary industrial applications like forklift trucks, container stacker and construction machinery. Our robust and scalable solution immediately improves productivity and efficiency for our end customers and significantly contributes to the safety and lifespan of their systems. With the full measurement taking place inside the cylinder, we can operate in any rugged industrial environment and are well-positioned even for the most demanding automation and autonomy use cases. Reach out to us to learn more about our existing products and discuss individual requirements.

Offshore sensors

In offshore drilling for oil production, Riser Tensioner cylinders are used as a stabilization system for drillships and platforms. The modern Direct Acting Tensioner cylinders guarantee a predefined tension of the drill string and compensate for all movements of the drillship, e.g. from sea swell and fluctuating waves. The system consists of six hydraulic cylinders mounted directly between the riser on one side and the derrick on the other side. Alternatively, the combination wire-line tensioner and drill string compensator is used. All three types of cylinders require a displacement measuring system in order to be able to compensate for the movement of the drillship in a controlled manner. The Astyx MPS microwave sensor (ATEX Zone 1 certified) is ideally suited for harsh conditions at sea. Currently, only nitrogen on the antenna side is used as operating medium. The following diameters can currently be delivered:

Careers

We are a fast-growing team pushing the boundaries of current technology. We enjoy team spirit, flat hierarchies, an open mindset, a passion for innovation and a high level of independence. We are in a brand-new office building with a state-of-the-art laboratory and production facility. Reach out to us if you want to work on the next generation of sensors!

Contact

International:

Astyx MPS GmbH

Caroline-Herschel-Str. 4

85521 Ottobrunn

Germany

info@astyx-mps.de

North America:

Verve MPS

5000 Centregreen Way, Suite 500

Cary, North Carolina 27513-5821

USA

info@verve-mps.com